Starting at around $1000 USD, anyone can pick up a high quality, high resolution, high color gamut, archival pigmented ink, color printer. In the hands of a professional these systems allow for the highest grade of gallery and museum print creation. Two notable professional printer manufacturers are Epson and Canon, and much like the differences between Canon and Nikon, so are the relative quality merits of these printers. As of early 2018, Epson has a slight edge on color gamut, print head resolution, and driver capabilities. Canon has an edge on print feeding. Both however are destroying your digital negative as it rolls out of the printer. So, the score is about even.

What was that last bit? Epson destroys your prints? SLANDER! NONSENSE! YOU ARE HOLDING IT WRONG! Canon as well?! Nonsense!

Pizza Wheels and Spiked Rollers

The design of Epson Canon art/museum quality printers is to roll the media off the platen via a plethora of small spiked rollers, much like the pattern tracing wheel tool used in the clothier trade. Only smaller. And pointier. And rows and rows of them. Canon has a vacusuck platen assist, but only as an assist to keep the medium perfectly flat under the print head.

The design of the media carriage using these ‘pizza wheels’ allows the paper to be moved through the platen as the image is laid down by the print head. The need for the many-up super pointy rollers is to grab the media as finely as possible on the printed surface without smooging the newly printed ink and roll the paper out of harms way.

The downside: Pizza wheel marks on glossy media where the ink and gloss surface are marred by the pointy rollers in a consistent tractor feed or railroad track pattern. Under bright light, at an angle, these vestigial marks are plainly seen, and no amount of adjustment or ‘doing it right’ will make the marks go away. A change of paper to less gloss will alleviate the issue as there will be no shiny surface to poke holes into, thus no evidence of the drama perpetrated upon the media. All well and good. Don’t use high gloss media in Epson/Canon printers if there is a chance the resultant print will be exposed to lighting that reveals the track marks.

This brings us to Digital Negatives - printed on glossy overhead projector (OHP) material, used for making contact prints where light shines down through the negative and onto your light sensitive paper. This OHP material is made of clear polyester sheets coated with grains of clear silica or ceramic. The opacity of the various manufacturer's material varies with Bergger PN100 and Arista-II digital negative OHP being the least opaque through Pictorico TPU100 in the mid-range to Pictorico TPS100 as the highest opacity digital negative material. All are decent materials for creating digital negatives, good choices for those who with preferences.

Pizza Wheel Marks and OHP for Digital Negatives

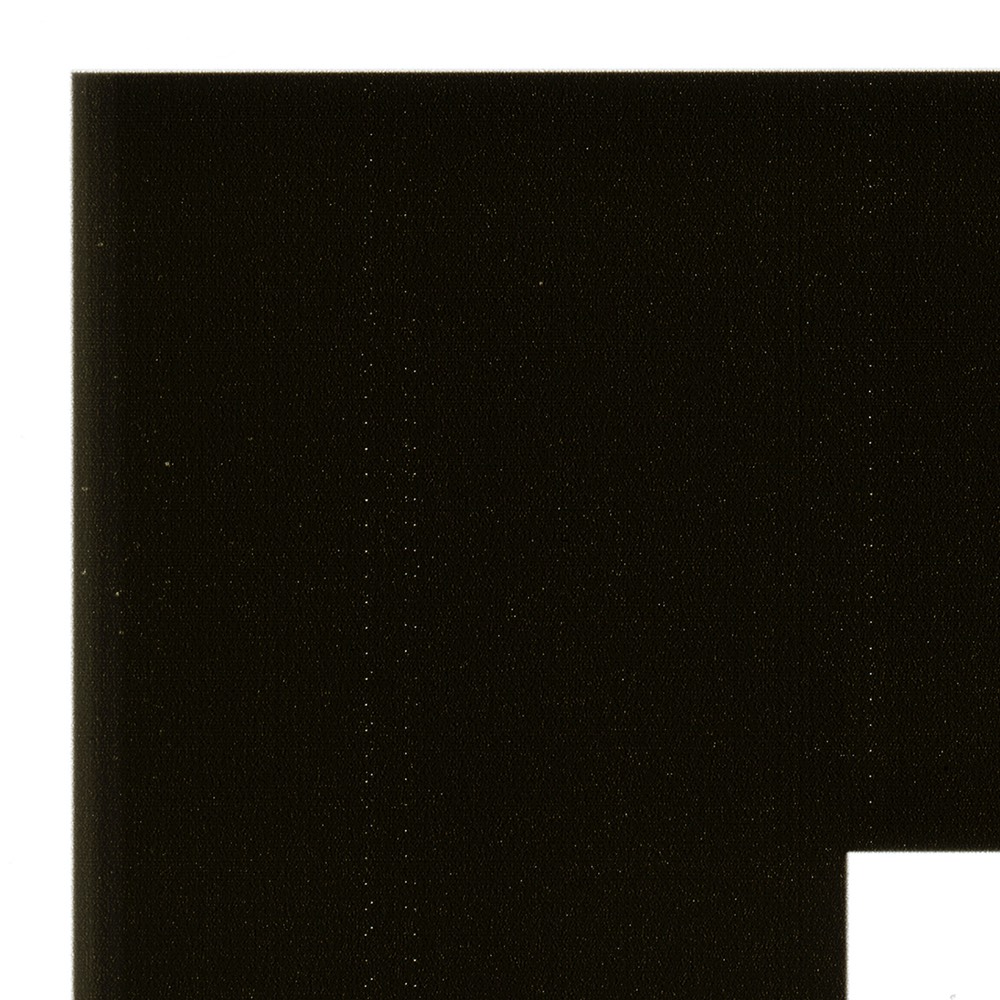

It turns out, who would have thought, that these rollers on Epson & Canon printer designs make teeny little holes in the newly printed ink laid down when printing a digital negative. Turns out these teeny little holes in a railroad track pattern in the ink are plainly visible when shining a light through the negative. Turns out that the resulting print, when exposed to light with this negative, will also have teeny little dark spots due to light passing through the negative's track marks onto the light sensitive emulsion. Thus effectively destroying the print. Maybe you can call these tracks ‘water marks’, maybe not. The heavier Pictorico TPS100 OHP seems best at hiding these marks due to its thickness of ink carrying silica/ceramic substate - tracks still visible however when looking closely at the negative and resultant print.

If you are set with a nice Epson or Canon archival quality printer, and you make the occasional digital negative, best to use Pictorico TPS100 to hide as much as possible the Pizza Wheel Effect. If creating digital negatives are your primary use, best to make a yet to be determined printer choice. Current thinking is the Epson P5000 which employs the wheels of derth half way through an A3+ sheet of media…so this is still not optimal. Might it be possible to work around this by adding 50% of dead zone to a custom media height at the end, keeping the important printed bits cleared of these wheels? An expensive experiment to run unless one has access to an Epson P5000 to test this out on.

At the end of the day we are still on the lookout for a printer capable of not destroying our negatives.

Scanned negative, marred from an Epson P800 printer and Arista-II Inkjet OHP 7-mil Transparency Film. Similar effect from Canon Pro-1000.